Membrane Bio-Reactors

CANON INTERNATIONALMembrane filtration has a major role in water and wastewater treatment, which is superior to conventional water technologies with a proven better performance and more efficient economics.

Why Canon International’s MBR?

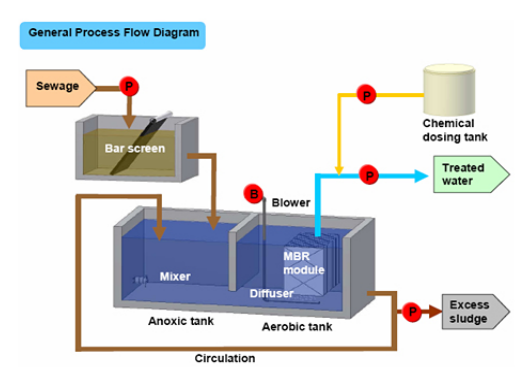

CANON INTERNATIONAL’S MBR technology is developed to meet stringent treated water quality for sewage and Industrial wastewater. It’s a membrane reactor-based design for biological treatment of effluent.

A Membrane bioreactor (MBR) processes are mainly used for wastewater treatment (WWT) by using microfiltration (MF) or ultrafiltration (UF) and integrating them with a biological process like a suspended growth bioreactor. The membranes are employed as a filter removing the solids which are developed during the biological process, which gives a clear and pathogen free product.

INDUSTRIES:

- food and beverage − high in organic loading

- petroleum industry − exploration, refining and petrochemical sectors

- pharmaceutical industry – have active pharmaceutical ingredients (APIs)

- pulp and paper industry − high levels of suspended solids, COD and BOD

- textile industry effluent − re-biodegradability, toxicity, FOG content and colour

- landfill leachate − wide variety of dissolved and suspended organic and inorganic compounds

- ship effluents − legislative requirements and space restrictions.

- Industrial versus municipal treatment

BENEFITS :

- High quality effluent

- Independent HRT and SRT

- Small footprint

- Consistent performance

- Low sludge production

- Less sludge dewatering